For this, it combines its LASERTEC SLM models and LASERTEC 3D and LASERTEC 3D hybrid series with the machining centers from its broadly diversified machine portfolio and a holistic advisory service. Furthermore, the company’s portfolio includes four complete process chains for additive processes using the powder nozzle or powder bed technologies. Presently, several companies are leveraging additive manufacturing for their machines and products.Įstablished in 1948, DMG MORI Company Limited is one of the leading companies providing its customers with turning and milling machines, the Advanced Technologies ULTRASONIC, LASERTEC as well as automation and digitization solutions for automotive, aerospace, die and mold, as well as medical industries. Thus, manufacturers of every size are looking at additive manufacturing as a complement to existing and traditional manufacturing methods. If implemented properly, additive manufacturing can significantly reduce material waste, reduce the number of production steps, inventory being held, and reduce the amount of distinct parts needed for an assembly. The advances in technology and changing customer needs are further fueling the use of additive manufacturing methods. The hybrid machine makes it possible to build additive parts up from scratch, as well as add features onto machined parts or repair damaged components.Additive Manufacturing has transformed the manufacturing industry over the past few years.

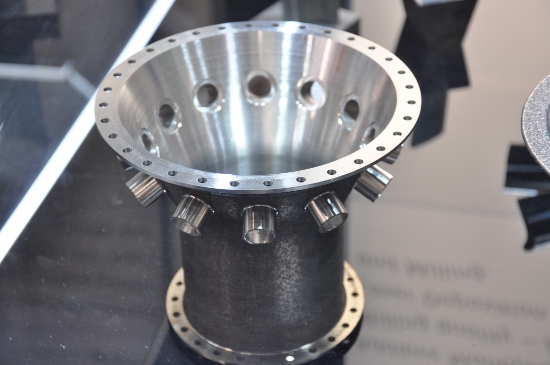

The machine combines five-axis CNC milling capabilities with a powder-fed laser deposition head to enable both additive and subtractive operations in the same cycle. Fiebig focused his talk on what was, in many ways, the centerpiece of the event: PTooling’s DMG MORI Lasertec 65 3D hybrid manufacturing system. Gregory Hyatt, senior vice president and CTO of advanced solutions development for DMG MORI USA and Matthias Kuehnelt of Hoedtke GmbH & Co. Jointly hosted by Canada Makes and the WindsorEssex Economic Development Corp., the event included presentations from Marv Fiebig, president of PTooling Dr. Manufacturers from Canada and the United States gathered at PTooling’s Amherstburg, Ontario, facility for an Additive Manufacturing forum April 27-28. A mural depicting some of the company’s key employees greets visitors just inside the door. PTooling opened its Ontario shop to Canadian and international manufacturing professionals interested in additive manufacturing.

0 kommentar(er)

0 kommentar(er)